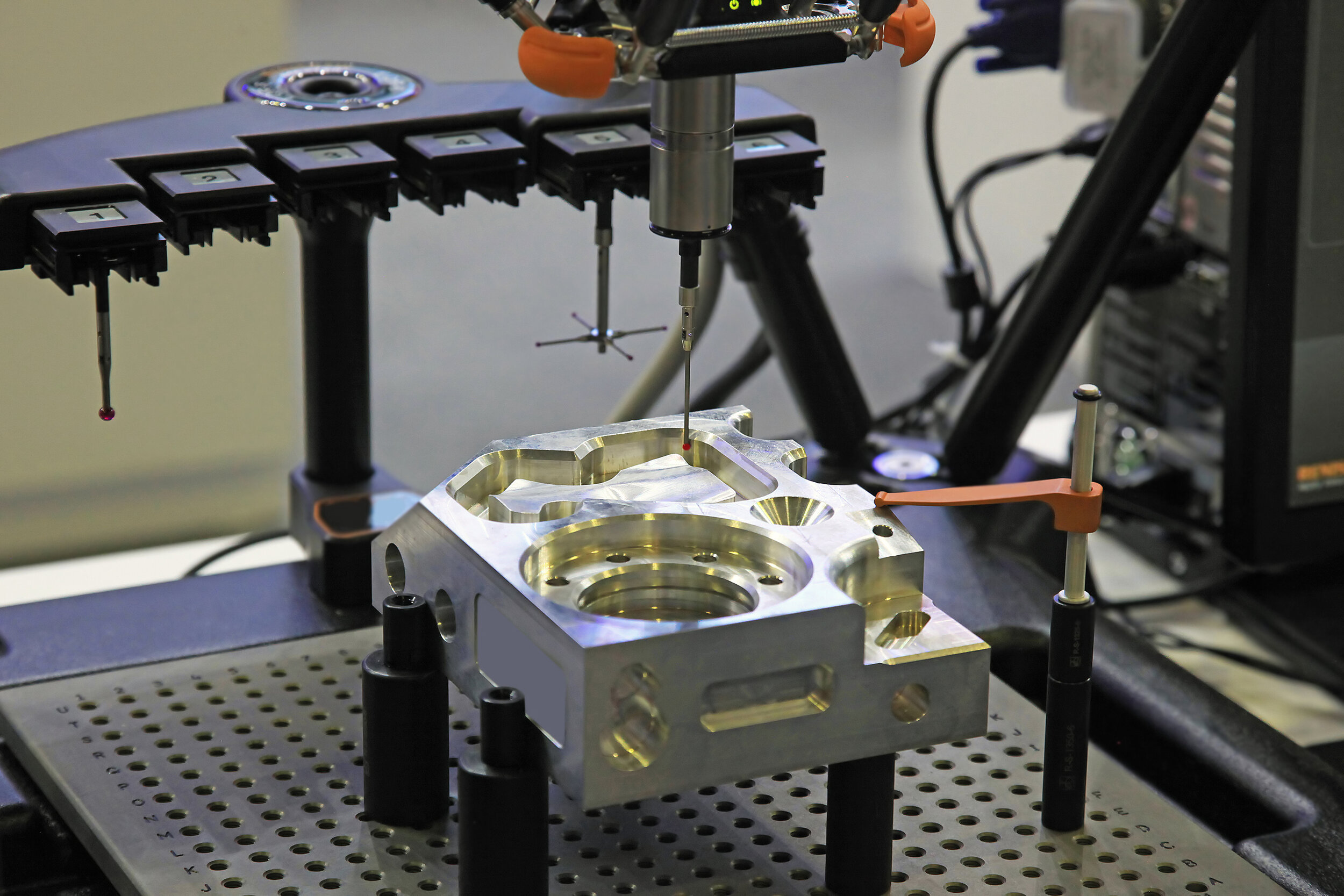

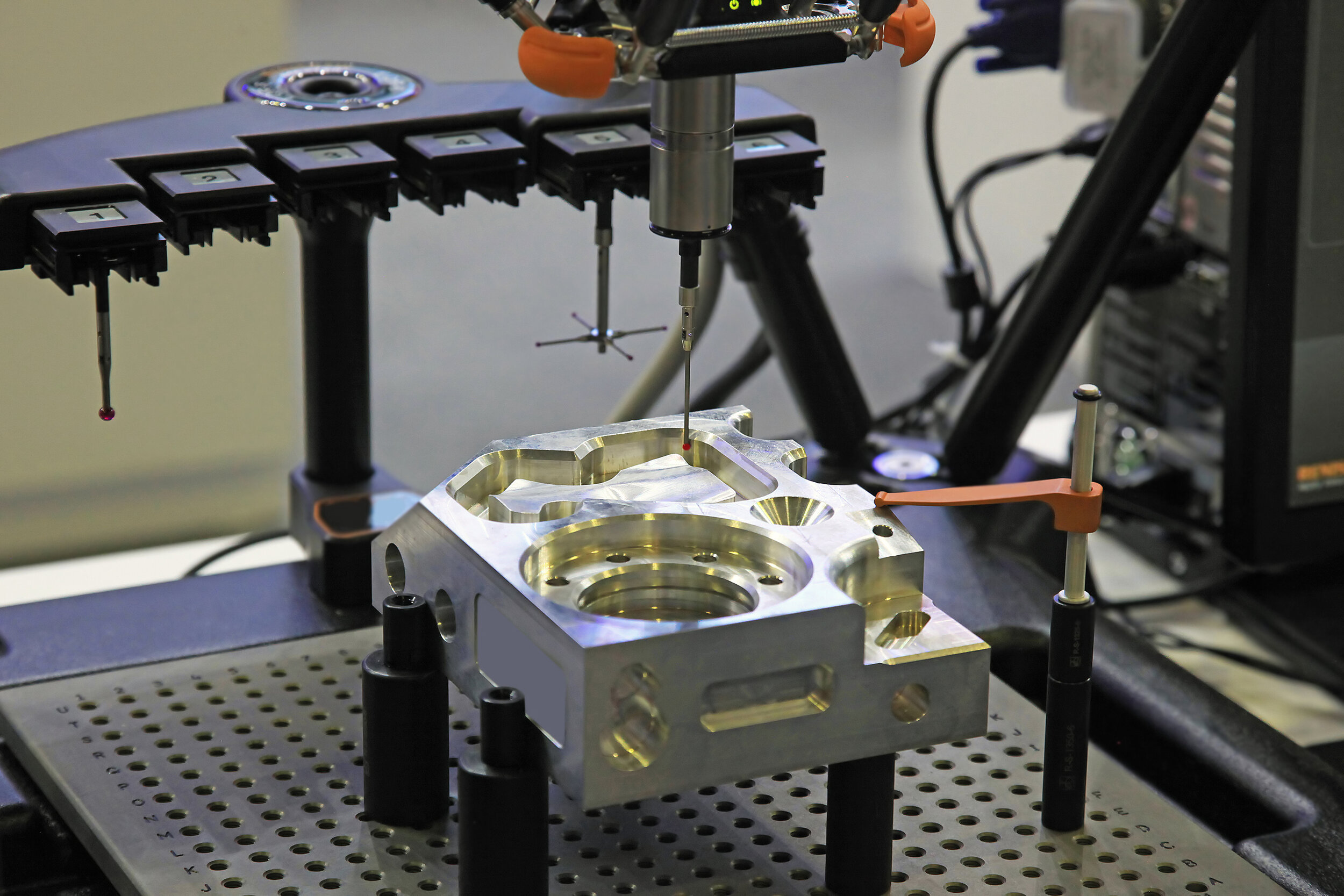

Prototype to Low Volume Production Precision Machined Components

CNC Milling | CNC Turning | Wire EDM

ISO 9001:2015 Certified | ISO 13485:2016 | AS9100:2016 Certified | ITAR Registered

Tool Technology, Inc. is a family-owned contract manufacturing machine shop in Middleton, MA. Our emphasis on precision and rigorous quality control has earned the trust of our customers, from start-ups to industrial giants like GE and Raytheon.

With ISO 9001/13485 and AS9100 certifications and an ITAR registration, we have the experience to serve the needs of high-tech, ultra-precision industries, including aerospace, medical, defense, and semiconductor machined parts. We specialize in repeat production contract manufacturing, as well as prototype machining to short-run production.

CNC Milling & Turning Services

CNC milling capabilities include 4-axis machines that deliver precision parts every time. Turning services include CNC turning as well as Swiss turning, allowing us to machine even the smallest of parts. We can achieve tolerances in the tenths across all our capabilities.

For aerospace, defense, medical, and semiconductor machining, common CNC machined parts include base plates, clamps, flanges, manifolds, and apertures. Our CNC turning expertise extends to optics, rings, threaded lenses, and threaded tubing, while our Swiss turning capabilities can produce ultra-precision parts like optics, lenses, pins, and custom hardware.

Certifications, Registrations & Facilities

Tool Technology is committed to the highest possible standards for process, machining, and quality control. We hold ISO 9001:2015 and ISO 13485:2016 certifications, an AS9100:2016 certification, and are an ITAR registered Massachusetts machine shop. These designations complement and enhance our expertise in aerospace and military/defense machining, and ensure that every part we make has proper documentation and traceability.

Our 20,000 square foot facility is designed for innovation and accuracy. Our equipment includes a range of CNC milling, CNC turning, and Swiss turning machines, as well as Conventional and Wire EDM capabilities. To ensure quality control, our quality inspection equipment includes the cutting-edge Hexagon Global S, an automated, fully programmable, and fully autonomous CMM.

Our vision is to build committed relationships with our customers through quality manufacturing, engineering expertise, competitive pricing, and on-time delivery.

Be the first to know about events and updates, including tech upgrades and new capabilities. Join the Tool Technology mailing list.